IC Engine Training

Last Update

Jan,01 1970Category

Mechanical EngineeringDescription

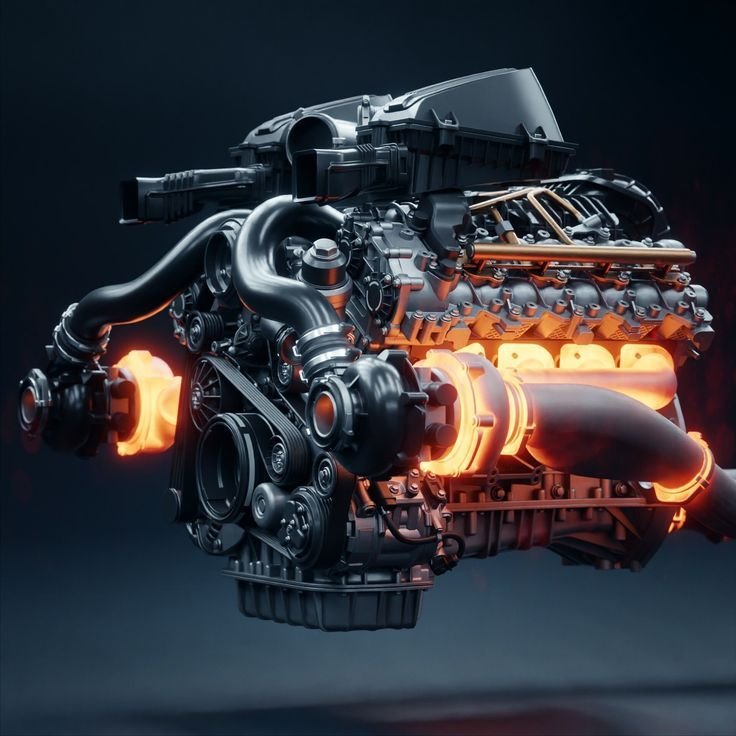

Module 1: Introduction to IC Engines

-

Types of IC engines: SI (Spark Ignition) and CI (Compression Ignition)

-

Engine components and their functions

-

Basic working principles

Module 2: Thermodynamics of IC Engines

-

Air-standard cycles (Otto, Diesel, Dual)

-

Combustion process and fuel-air mixture

-

Engine efficiency and performance parameters

Module 3: Engine Components and Materials

-

Cylinder, piston, crankshaft, valves, camshaft

-

Materials used in engine construction

-

Cooling and lubrication systems

Module 4: Fuel Systems and Ignition

-

Carburetors and fuel injection systems

-

Ignition systems: magneto, coil, electronic ignition

-

Emission control technologies

Module 5: Engine Testing and Performance Analysis

-

Measurement of power, torque, and fuel consumption

-

Brake and indicated thermal efficiencies

-

Emission testing and standards

Module 6: Maintenance and Troubleshooting

-

Common engine faults and their diagnosis

-

Routine maintenance procedures

-

Tools and techniques for repair

Module 7: Advances in IC Engines

-

Turbocharging and supercharging

-

Alternative fuels and hybrid engines

-

Recent trends and future prospects

Practical Sessions and Projects

-

Dismantling and assembling an IC engine

-

Performance testing on engine test rigs

-

Emission analysis and tuning

Requirements

What is an IC Engine?

An Internal Combustion (IC) Engine is a heat engine where the combustion of fuel occurs inside the engine cylinder, producing power to drive vehicles, machinery, and equipment.

Why Learn IC Engine Technology?

-

Fundamental knowledge for automotive and mechanical engineers

-

Essential for maintenance, repair, and design of engines

-

Understanding engine performance, emissions, and efficiency

-

Opens career opportunities in automotive service, manufacturing, and research

Curriculum

-

LevelBeginner

-

Lectures10 Lectures

-

Duration10h/30m

-

CategoryMechanical Engineering

-

LanguageEnglish

-

CertificateYes

.jpg)