Programmable Logical Controllers Training

Last Update

Jan,01 1970Category

ECE/ EEEDescription

Module 1: Introduction to PLCs

-

What is a PLC?

-

History and evolution

-

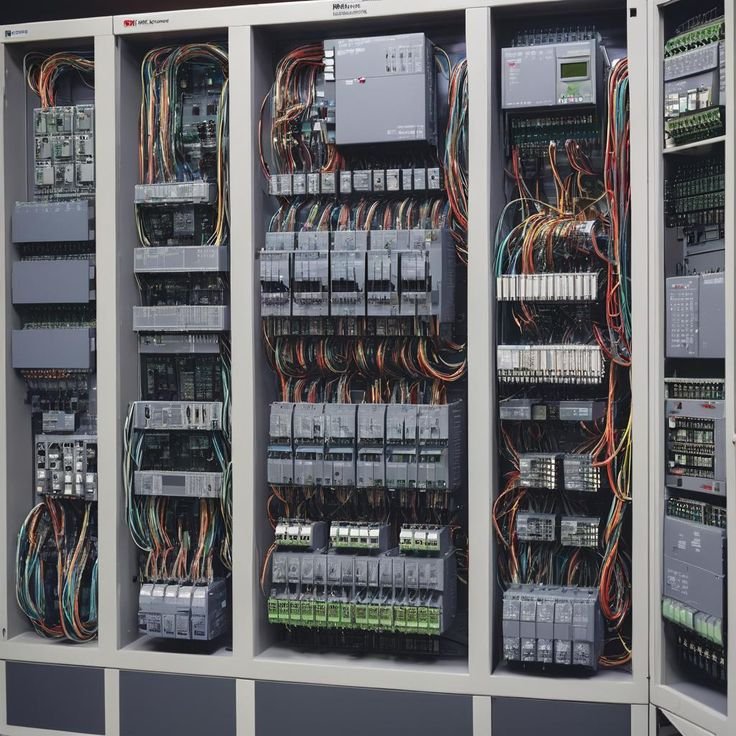

PLC hardware components and architecture

-

Input/output modules and types

Module 2: PLC Programming Fundamentals

-

Programming languages overview: Ladder Logic, Function Block Diagram, Structured Text

-

Basic instructions: contacts, coils, timers, counters

-

Programming software overview (e.g., Siemens TIA Portal, Allen-Bradley RSLogix)

Module 3: PLC Hardware and Wiring

-

Input and output devices

-

Wiring techniques and standards

-

Signal types: digital vs analog

Module 4: Advanced PLC Programming

-

Timers and counters in-depth

-

Comparison instructions

-

Data handling and manipulation

-

Subroutines and modular programming

Module 5: Communication and Networking

-

Industrial communication protocols (Modbus, Profibus, Ethernet/IP)

-

PLC to PLC and PLC to HMI communication

-

SCADA integration basics

Module 6: Troubleshooting and Maintenance

-

Diagnosing faults in hardware and software

-

Use of diagnostic tools and simulators

-

Preventive maintenance strategies

Module 7: Practical Projects and Simulation

-

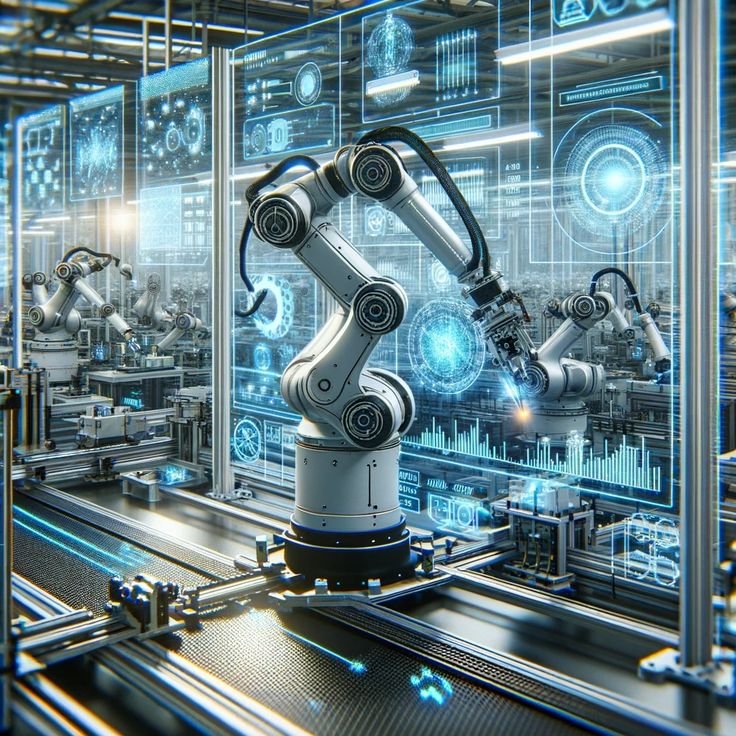

Designing simple automation circuits

-

Conveyor belt control system

-

Traffic light control system

-

Simulation using software tools

Requirements

What are PLCs?

Programmable Logic Controllers (PLCs) are industrial digital computers designed for automating electromechanical processes such as control of machinery on factory assembly lines, lighting systems, and robotic devices.

Why Learn PLC?

-

Essential skill for industrial automation and control systems

-

Widely used in manufacturing, automotive, energy, and process industries

-

Opens career opportunities as Automation Engineer, Controls Technician, and Systems Integrator

Curriculum

-

LevelAdvanced Level

-

Lectures10 Lectures

-

Duration10h/30m

-

CategoryECE/ EEE

-

LanguageEnglish

-

CertificateYes

.jpg)